1943 Memorandum for the Construction of Hanford

Written in September 1943, about nine months after du Pont and the government signed an informal letter-of-agreement that initiated work on Hanford, the Memorandum tells how extremely reluctant du Pont was to take on the massive and highly speculative project. It describes the technical aspects of the nuclear transmutation process for changing uranium into plutonium and points out the various ways in which the entire venture could fail. It foretells in chilling detail the possibility of a catastrophic accident like that which occurred 43 years later at Chernobyl.

Hanford Document No. HAN-43508, September 1943

The Plant and processes described herein and their description herein, are based upon information developed through research by the University of Chicago and others, and furnished to the Contractor at the instance of the Government. The specific process components and types and sizes of equipment selected for use have been recommended by the Contractor, concurred in by the University of Chicago and accepted by the Government, on the basis of what are believed to be the best available data; it being understood that changes may be made from time to time as more research data are acquired and as detailed design, construction, and operation of the Plant proceed.

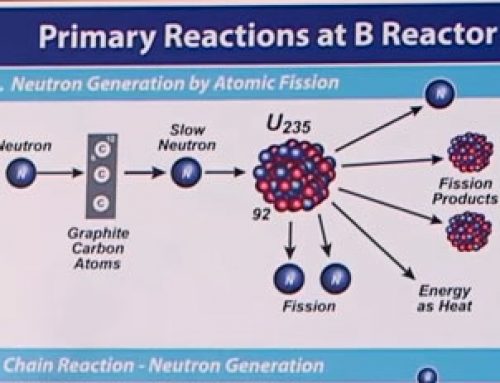

Under the Contract the Contractor will attempt to design, construct and operate a Plant for the production of a new chemical element by transmutation of an existing element, uranium, to the new element. The new element has been named “Plutonium”. The Plant to be provided under the Contract will have an estimated output when in normal operation at rated capacity, of about one pound of Plutonium per day. About four-millionths (0.000004) of a pound of Plutonium has been made to September, 1943. This quantity of Plutonium has been made by laboratory methods not adaptable to large-scale operation and different from the transmutation process to be used in the Plant to be provided under the Contract. The first experimental demonstration of the transmutation process was made on December 2, 1942. The quantity of Plutonium produced to date by such experimental demonstrations is so small as to make impracticable its chemical separation and recovery in tangible amount from the uranium used in the demonstrations.

The shortness of the time available for research since December, 1941, as well as the absolutely pioneering character of the Plutonium development, should be borne continually in mind in reading this Memorandum. The research has been conducted, and is proceeding, in the face of serious handicaps which are inherent in the nature of the transmutation process. For example, to carry out the transmutation process on the laboratory scale, even at an infinitesimal rate of production, there is required a transmutation unit of nearly the same physical size as one of the more complex large-scale units now to be constructed. Even such a laboratory unit requires about forty-five tons of uranium and uranium oxide; these amounts were not available in adequate quality until late in 1942. No such laboratory unit would produce enough Plutonium for normal laboratory-scale chemical research on Plutonium recovery, and only minute amounts of Plutonium could be made in other ways; therefore, difficult micro-chemical procedures have had to be used in developing a Plutonium recovery process. Intense radioactivity is encountered throughout both transmutation and recovery research.

In June, 1942, in preparation for large-scale operation, the Corps of Engineers assumed responsibility for direction of the Plutonium project. The contractor was first made aware of the nature and objectives of the Plutonium development in November, 1942, following a request by the office of Scientific Research and Development and the Corps of Engineers to the Contractor to render an opinion regarding the feasibility of building and operating large-scale plant for Plutonium production. In August and September, 1942, at the request of the Corps of Engineers, the Contractor had lent chemical engineers to the University of Chicago for work stated to be of great military importance but not otherwise described. In October, 1942, at the request of the Corps of Engineers, the Contractor had undertaken by Letter Contract dated October 3, 1942, to furnish engineering assistance in the design of a semi-works recovery plant but was without knowledge of the transmutation process and the objectives of the development for which the semi-works recovery plant was to be used.

In November, 1942, the Contractor assigned personnel who spent three days in a review of the Plutonium development at the University of Chicago as requested by the Government. Emphasizing its complete inexperience in the field involved in the development, the Contractor then reported to the Government that it found obvious grave difficulties but no apparent fatal obstacles to an attempt to secure early large-scale production of Plutonium, presuming favorable outcome of experiments yet to be made. The Government then requested the Contractor to undertake large-scale production of Plutonium, stating to the Contractor that the war-importance and urgency of the Plutonium development demanded that it proceed promptly to the production stage in spite of important gaps in the information normally considered necessary for design, construction and operation of large-scale plant. Having learned during its investigation of the Plutonium development that research was being conducted on two other processes for obtaining products capable of the same military use as Plutonium, the Contractor suggested that the relative merits and degrees of assurance of success of these other processes should be reviewed and compared before the Government decided finally on any program involving Plutonium production. As a result of this suggestion, the Office of Scientific Research and Development and the Corps of Engineers borrowed from the Contractor three employees to serve as members of a committee of five to investigate and compare the Plutonium and alternative developments. The committee spent six days in a review of the Plutonium process and the two alternative developments. Following report of the committee to the Government in December, 1942, the Contractor was again asked by the Government to undertake large-scale Plutonium production. The Contractor stated its reluctance to do so, emphasizing again its inexperience in the field involved. The Government insisted in its request. Thereupon the Contractor accepted the assignment by signature of a Letter Contract on December 21, 1942, and began actively to organize personnel for the work in January, 1943.

Under a supplemental Letter Contract signed January 8, 1943, the Contractor is designing and constructing a semi-works Plutonium plant to be operated by the University of Chicago. In this semi-works plant, the transmutation process to be used in the large-scale Plant under this Contract can, it is estimated, be operated at a maximum capacity which is four-tenths of one per cent (0.4%) of the designed capacity of each of the large-scale Plant units. However, the transmutation equipment in the semi-works plant will differ from the transmutation equipment in the large-scale Plant in some critical respects; this is in order that the semi-works plant can be erected more quickly and so, if it operates successfully, may produce promptly the small amounts of Plutonium which it is designed to produce and which are urgently needed for experimental purposes. Moreover, the design and construction of the large-scale Plant must proceed simultaneously with the design and construction of the semi-works plant; consequently, the design and construction of the large-scale Plant cannot take normal advantage of semi-works operating data and experience. The large-scale Plant will therefore represent not only the first attempt ever made to transmute one chemical element into another on a production scale, but also an effort to do this in a Plant designed substantially on the basis of data determined on the laboratory scale only.

The treated uranium discharged from the transmutation unit after three months’ operation at rated capacity is expected to contain, on the average, about twenty-five hundred-thousandths (0.00025) parts by weight of Plutonium, together with about an equal quantity of highly radioactive chemical by-products. The uranium containing Plutonium must be handled mechanically by indirect means and surrounded by shielding (about one foot of lead) to protect against its radioactivity, and will spontaneously evolve sufficient heat to require constant cooling during handling and during much of the necessary two months’ storage (under 16 feet of water for shielding) before it can be treated further. The material will then be dissolved in acid and the Plutonium will be separated from the uranium and radioactive by-products by a series of chemical precipitations and re-solutions carried out, because of the radioactivity, by remote control behind shielding (about 7 feet of concrete) and without the opportunity for direct observation of the operation.

Returning to the process carried out in the transmutation unit, usually referred to as a “pile”: Neutrons continually escape from the outer portions of the mass of uranium and graphite. Too great a loss of neutrons in this way would prevent the neutron chain reaction. Consequently, the pile must be made large enough so that its surface is small in relation to its volume; i.e., the transmutation process will “go” only in large piles. Each large pile requires large quantities of very pure graphite (about 1500 tons) and of very pure metallic uranium (about 200 tons). Since only limited quantities of uranium are available, the piles to be designed, constructed and operated must be limited in number. Therefore, in order that the desired quantity of Plutonium may be made promptly, each pile must be designed for, and operated at, a high capacity; i.e., at a high rate of heat removal. It is proposed to build and operate three piles, each rated at 250,000 kilowatts. The 250,000 kilowatt capacity is so great that the design of the proposed piles is thereby made slow and difficult; and the operability of the piles is doubtful, particularly their operability at full rated capacity. Nevertheless, it is believed that the proposed pile capacity represents the best choice when consideration is given to the factors of availability of construction and other materials, time for construction, cost, safety, probability of successful operation, estimated output, and urgency of need of Plutonium for military purposes.

The very large amount of heat produced along with the Plutonium must be dissipated in the face of severe limitation of the means to be used for heat transfer and heat removal. The sizes, shapes and space-relationships of the graphite and uranium components in each pile have been shown by laboratory tests to be critical to the success of the transmutation process, so that they must be adhered to closely, regardless of their effect on heat removal and other operational requirements. Only minimum amounts of other materials than uranium and graphite may be built into the pile to serve for uranium-handling and heat-removal purposes; and of the very few having a sufficiently small effect on the neutron reaction, only aluminum and magnesium are available for use in sufficient quantity and suited for use as structural materials. Choice of cooling agent to be used is limited by the fact that many otherwise suitable cooling agents would be destroyed by the transmutation operation. The cooling agent must be available in sufficient quantity and efficient when applied under conditions which do not too greatly interfere with the neutron reaction. The chosen cooling agent is water, filtered, further purified and refrigerated if necessary, forced through the pile, and then discarded. Recirculation of cooling water is prevented by the fact that the water would become increasingly corrosive upon recirculation, because of the effect of radioactivity upon it during its passage through the pile.

Each pile will be an approximate cube (about 28 feet long, 36 feet high, and 36 feet wide) built of graphite blocks about four inches square and of varying lengths. The pile will stand on a deep concrete foundation and be otherwise totally and closely surrounded by a radiation-absorbing shield about five feet thick, made of iron, steel and pressed wood. Horizontally through the pile and the end walls of the shield will pass about fifteen hundred (1500) aluminum tubes, spaced uniformly on about eight-inch centers. Each tube will be of about one and sixty-one one-hundredths (1.61) inches inside diameter and about six hundredths (0.06) of an inch wall thickness. Each tube will carry throughout most of its length, cylinders of uranium about one and thirty-eight one-hundredths (1.38) inches in diameter and eight inches long. Ribs projecting from the internal surface of the tube will support the cylinders centrally in the cross-section of the tube. Each cylinder will be sheathed in a tight jacket of aluminum about three hundredths (0.03) of an inch thick. In the narrow annular space about eighty-five thousandths (0.085) of an inch wide, between each aluminum tube and the aluminum-sheathed uranium cylinder within it, will flow the cooling water. The uranium must be sheathed in aluminum as described in order to protect it from chemical action by the cooling water, and in order to prevent the passage of radioactive materials from the uranium to the water.

To avoid undue interference with the neutron reaction, only a minimum amount of cooling water may be present in the pile at any one time; yet very large amounts of water (about 30,000 gallons per minute per pile at the proposed capacity) must flow through the pile for safe and sufficient heat removal. The flow of these large amounts of water through the pile without more than a very small fraction (about 400 gallons) of the total water flow being in the pile at any time, requires the use of the very small water channels in the pile and consequently, of very high water velocities through these channels. Even if the water is purified by the best feasible means, it may corrode away the aluminum sheaths or tubes, or impurities or corrosion products deposited from the water may partially or wholly block the narrow water channels, necessitating operation at a lower output or even shutdown and possible abandonment of a pile.

The “radioactivity” which accompanies the formation of the Plutonium is so great that the energy of radiation within each pile will be equivalent to the energy of radiation from about 1700 tons of radium, or over 1,000,000 times as much radium as is known to have been produced since the discovery of radium. The existence of this enormous amount of radiation during normal pile operation requires the beforementioned complete, heavy shielding (about 5 feet of iron, steel and pressed wood) to absorb the radiation to protect operating personnel. Without such shielding, exposure to the radiation from the operating pile for even a few seconds, would be fatal. Insufficient information is available to provide protection with complete assurance of adequacy, and provision of protection calculated to be adequate complicates and limits the design, construction and operating practicability of the pile greatly. Since the radiation cannot be detected by the senses, injury to operating personnel can be minimized only by elaborate precaution and careful surveillance. The presence of large amounts of highly radioactive material represents an ever-present hazard to personnel in surrounding areas should control of the process fail or be interrupted.

While many experiments have been made concerning the effects of extreme radiation on the properties of the materials of construction and of the cooling agent to be used, there remain uncertainties and hazards. Even the stability of the graphite under intense radiation is questionable. Assuming that too great “normal” corrosion of aluminum sheaths and tubes can be prevented by never allowing the cooling water to attain too high a temperature, under the influence of the radiation the rate of corrosion may nevertheless become so great as to make operation of the piles, especially at rated output, impracticable for even short periods of time. The large amounts of effluent water are calculated to be safe for discharge to the large river adjacent to the location of the piles, but experiments being made to attempt to prove this point in advance of actual plant operation, may be inconclusive. Large retention reservoirs to permit decay of radioactivity before return of water to the river, are planned.

Not only does the overall intensity of radiation which will be experienced exceed manyfold that which has been experienced previously, but the nature and distribution of the radiation present new problems. In addition to radiation of the types (beta and gamma rays) previously experienced in relatively small amounts, neutrons will be encountered for the first time in enormous concentrations. Information concerning the physiological effects of neutrons and their effects on materials of construction is very incomplete. A considerable amount of radiation may be present in the form of neutrinos, hypothetical particles of which little is known.

Once operated, a pile will not become substantially completely inactive until months have passed, even if all the uranium has been discharged from it. Radioactivity will have been induced in the graphite, aluminum, iron and steel in the pile and shield. This may make it difficult, if not impossible, to modify or repair a pile once it has been operated, except after a long waiting period for decay of the radioactivity. Consequently, even if the design of the pile proves to be adequate and even if no serious accident occurs in operation, a series of minor leakages or breakages may require complete abandonment or shutdown for a period so long as to make the shutdown equivalent to abandonment for present war purposes. The possibility of abandonment can be measured by the fact that the failure of as few as 15 of the most critically-placed of the 1500 tubes in each pile, might make the pile inoperative by preventing the neutron reaction.

As pile operation proceeds there will be an increasing accumulation of Plutonium and of radioactive by-products in the uranium in the pile. It is known that the by-products may affect the neutron chain reaction adversely, counteracting the known accelerating influence of the increasing concentration of Plutonium. It is not known whether the overall effect will be to speed the reaction or to slow it down. Conceivably, the pile may be “poisoned” by the by-products so rapidly as to delay or prevent the building up of the planned concentration of Plutonium in the uranium, or perhaps even to preclude the attainment of a Plutonium concentration sufficient for practicable recovery. To obviate this, it is necessary to provide excess reactivity in the pile, and that can be done only by keeping the amounts of neutron-reaction-inhibiting water and aluminum in the pile very small; so small that the narrow pressure-water channels may block with water impurities or corrosion products, and the thin aluminum tubes and sheaths are fragile and will be permeable after only slight corrosion. Radiation-disintegration of the graphite, blockage of water channels, breakage or leakage of tubes or sheaths, and the radioactive by-product effect on the pile reaction, represent known possible causes for failure to attain Plutonium production as planned.

The heat produced by the operation at full capacity of the three piles to be constructed under the Contract is calculated to be equivalent to about three-fourths of the total authorized power output from the Grand Coulee Dam (1,000,000 kilowatts); presuming that it proves to be possible to operate the Plant at a rate approaching this capacity. For future peacetime plants for Plutonium manufacture, it may be practicable to develop and provide means to convert the heat evolved in the transmutation process into useful power. This cannot be attempted in the Plant to be built under the Contract because neither time nor the necessary technical information is available for the purpose. In fact, the mere removal and dissipation of pile heat, no matter how wastefully, represents one of the major problems of design and operation. Should the supply of cooling water to an operating pile be interrupted for even a few seconds, disaster of catastrophic proportions may immediately result.

In order that the formation of Plutonium may proceed successfully and that catastrophe may be avoided, it is necessary not only that there be an uninterrupted and sufficient overall flow of cooling water to the pile, but also that the flow of water at each point within the pile be adequate to remove the quantity of heat being generated at that point. Distribution of water at high pressure (200 pounds per square inch) to each of the 1500 tubes in the pile, in the amount required by each tube, is a difficult engineering problem requiring complicated piping arrangements. Despite such difficulties, the water flow must be continuous, sufficient, and adequately distributed under all conditions. Two sets of water pumps driven by independent power sources will be installed, and water reservoirs for emergency use (including overhead reservoirs) will be provided; but there remains the danger of stoppage or breakage of water piping.

Water flow must continue even when the pile is shut down in the course of normal operation. As has been described, the rate of the neutron chain reaction will be controlled by moving rods containing cadmium or boron, into and out of the pile. The reaction will stop when enough rods are inserted into the pile to a sufficient depth; and “safety” rods designed for automatic, “instantaneous” (1.5 seconds) insertion will be provided, as well as other safety measures, all to be actuated by stoppage of water flow or other operating accidents. But heat generation will not cease immediately upon application of the controls. The neutron reaction will stop only as the rods absorb neutrons, and a few seconds must pass before neutron absorption is substantially complete. Moreover, after the neutron reaction has ceased, the radioactive materials in the pile will continue to evolve heat at a rate starting at about one-tenth of the heat generation when the pile is operating at full capacity, gradually diminishing, and stopping only when all the uranium is discharged from the pile.

To appreciate the rapidity with which disaster might occur with a pile delivering high power, and the extent of the catastrophe which might follow upon the failure of all of the several safety devices which will be provided: Suppose that through some mischance, the water supply to the pile is interrupted for a few seconds, the control rods cannot be inserted immediately or completely, and all “safety shutdown” devices fail to act or act too slowly. Heat generation in the uranium cylinders will continue. The water surrounding the uranium in the control tubes of the pile will begin to boil in three seconds, and the boiling will travel swiftly in a wave from the central to the outermost tubes. A steam explosion of the pile may result. If this explosion is not too violent yet violent enough, it may save the situation by immediately disrupting the pile just sufficiently to disturb the critical space-relationship of the graphite and uranium and so causing the neutron reaction and the heat generation to cease. If the steam explosion is more violent, it will break open the pile and throw its radioactive contents to a distance dependent upon the exact force of the explosion. The pile will have to be abandoned, the area surrounding it will have to be evacuated, and casualties will have been caused by flying fragments or by exposure to radioactivity from those fragments or from the radioactive dust cloud which will be the factor that will most greatly extend the area affected by the explosion.

If a steam explosion does not occur or is so mild that it does not disrupt the graphite-uranium space-relationship in the pile, nevertheless the water will have started to boil in the control tubes of the pile as explained above. The large volume of gaseous steam formed by the boiling will rapidly push the neutron-absorbing liquid water out of the central tubes, whereupon the rate at which neutrons are produced throughout the pile, and consequently the rate at which heat is liberated throughout the pile, will increase swiftly and enormously, becoming progressively greater as boiling proceeds in a wave from the central tubes to the surrounding tubes so that the liquid water is expelled from more and more tubes. If this process is uninterrupted, i.e., if no steam explosion occurs, the water will be expelled from the outermost tubes of the pile within five seconds after the water has been expelled from the central tubes. Meanwhile heat will be liberated at the rate of many millions of kilowatts. (If all liquid water were instantaneously removed from the pile, heat generation would increase one millionfold in one second.) Meanwhile also, the temperature in the central tubes will have risen rapidly, passing successively through the melting point of the aluminum sheaths and tubes (1200EF.), the melting point of uranium (2600EF.), the boiling point of aluminum (3200EF.), and the boiling point of uranium (7800EF.). The melting of the aluminum and the uranium will not sufficiently disturb the graphite-uranium space-relationship in the pile to stop the neutron reaction and heat generation, if for no other reason than because the molten uranium will not have time to flow away before it reaches its boiling point. Beginning at the center of the pile, the aluminum and uranium will vaporize with explosive violence, literally bursting the pile apart, perhaps even before the water has been forced from the outermost tubes of the pile. The issuing uranium vapor carrying radioactive by-products, will ignite as it comes in contact with the air. The resulting cloud of extremely radioactive uranium oxide smoke will kill or injure persons exposed to it until it has spread over an area so great that sufficient dilution of it by air has been obtained. The affected area will have to be completely evacuated.

One phenomenon can prevent this catastrophe: Sufficient decrease in rate of the neutron reaction as the temperature rises, so that the reaction and heat generation level off before the temperature in the pile has reached a point such that catastrophe will result. It is known that the rate of the neutron reaction will be effected as has been described, by displacement of water from the pile. It is not known with finality and accuracy whether the neutron reaction will be slowed or accelerated by temperature rise in uranium in a pile in which the graphite-uranium space-relationships, the amount and position of aluminum, and the relative temperatures of uranium, aluminum and graphite are as they will be in the large-scale pile. Attempts have been made and are continuing, to determine accurately whether temperature rise will slow or accelerate the neutron reaction, and to what extent. Such experiments and measurements are difficult, especially when made outside a relatively small temperature range around the normal operating temperature of the pile (150EF.). As the result of the temperature tests carried out to date, it is believed that rise in temperature slows the neutron reaction to such an extent that the heat generation, and consequently the temperature, will level off at a point below the melting point of uranium (2600EF.). It is conceivable, though improbable, that rise in temperature might be shown to slow the neutron reaction within a temperature range, yet that slowing would shift to acceleration at higher temperatures which would be reached in the pile in spite of the slowed rate of reaching them.

If it be presumed that heat generation will level off at some temperature far below the boiling point of uranium, nevertheless disaster is still possible; inasmuch as the only condition necessary for the formation of the radioactive smoke cloud which is the hazard most to be feared, is that the uranium be exposed to the air at a temperature high enough so that it will burn to uranium oxide at a reasonably rapid rate. Such a temperature is the melting point of aluminum (1200EF.). At that temperature, the thin aluminum sheaths (0.03 of an inch thick) on the uranium cylinders will melt away, exposing the uranium. The uranium will then burn as soon as it comes in contact with air. Air will enter the pile relatively slowly through breaks in the water connections to the pile or through breaks in connections to the air-tight casing on the pile. Such breaks might have been caused by the original accident which interrupted the water flow to the pile; they would be caused by a relatively mild steam explosion after the accident. Air will enter the pile rapidly if the graphite structure itself is opened up. Such disruption of the graphite structure may be caused by steam explosion mild enough not to disturb the graphite-uranium space-relationship to a degree which will stop the neutron reaction, yet strong enough to shake the structure. Or expansion-disruption and air access to the pile may accompany or follow attainment of moderately high temperatures in the uranium, merely because of rapidly-formed large temperature gradients in the pile structure due to the greater heat generation and smaller heat loss in the center of the pile. The burning of even a small fraction of the 200 tons of uranium in the pile is sure to start combustion of the 1500 tons of graphite in the pile.

The treated uranium spontaneously produces heat and must be cooled continuously during handling and during the early part of its two months’ storage in order that it may not melt and burn to radioactive smoke. After storage it must be transported, properly shielded, to isolated recovery units. In these units the Plutonium will be recovered from the uranium and purified by chemical means, using dissolving, precipitating and filtering equipment which must be operated unseen and by remote control from behind shields (7 feet of concrete) calculated to be adequate to protect operating personnel against the extreme radioactivity.

When the treated uranium is dissolved in acid to start recovery operations, radioactive gas will be evolved. This must be vented to the atmosphere above the recovery units with sufficient dilution so that radioactivity from it may not injure operating personnel by radiating down to the ground from the sky with harmful intensity or by being carried back to the ground in harmful concentration by air currents. Radioactive xenon, the principal known radioactive gas which will be encountered in the recovery process, is so toxic that one cubic foot of it must be diluted in a cube of air two miles on each edge, before it can be breathed safely. Recovery operations must be limited to a small amount of Plutonium per recovery-batch, in order to avoid heat and explosion hazards from the Plutonium itself.

The chemical solutions involved in the recovery process are corrosive, and it has not been possible to determine conclusively whether corrosion will be increased to a prohibitive extent by the presence of the degree of radioactivity which will be encountered in the Plant as compared with the lesser degree available for laboratory experiments. The treated uranium will contain so small an amount of Plutonium that, when the Plutonium is precipitated from solution in the course of recovery operations, it will not form a visible precipitate in the solution. Consequently, by addition of suitable chemical reagents, bulky “carrier” precipitates must be formed along with the Plutonium precipitate throughout the recovery process. The chemical recovery process is an ionic process, and it has not been possible to test the process with materials and under conditions adequate to determine conclusively that the process will “work” in the presence of the intensity of radioactivity which will be encountered in the Plant.

Experimental development of the recovery process has dealt, all told, with about four millionths (0.000004) of a pound of Plutonium; and this small quantity has been made, not by the proposed transmutation process, but by cyclotron bombardment of uranium or chemical compounds of uranium. Only by conducting experiments in glassware on a micro-chemical scale has it been possible to work with anticipated Plant concentrations of Plutonium and anticipated Plant concentrations of radioactive by-products, and it is doubtful that the radioactive by-products so tested have been altogether representative of those to be met in large-scale operation. Extremely dilute solutions of Plutonium and radioactive by-products have been all that have been available for experiments in metal apparatus on a large laboratory scale. Therefore, in the development of the recovery process, non-typical raw material has had to be used, in micro-chemical quantity or at great dilution, and it has not been possible to carry out plant-type recovery operations in the presence of radioactivity even distantly approaching in intensity that which will be faced in the recovery units in the Plant.

Purification of Plutonium must be carried at least to the point where radioactivity is reduced to proportions requiring only normal precautions in handling and shipping. Purification to this degree requires removal of radioactive impurities so that the purified product possesses only one ten-millionth (0.0000001) as much radioactivity as the treated uranium entering the recovery units after two months’ storage. Plutonium is itself moderately radioactive.

No purification process can be established as adequate until treated uranium from large-scale pile operation at rated output has been purified to the desired degree. The impurities to be removed may turn out to be related qualitatively as well as quantitatively to the scale and rate of the transmutation operation; consequently new impurities may be encountered in uranium treated on the large scale. And until purification has been carried to the desired degree, it cannot be determined that the purification process is not selectively removing certain impurities and leaving other impurities whose presence cannot finally be tolerated.

For the sake of simplicity, the transmutation process has been described as the direct transmutation of uranium to Plutonium. Actually another element, “Neptunium”, is first formed. Upon relatively rapid radioactive decay, Neptunium spontaneously transforms itself into Plutonium. Since Neptunium is dangerously radioactive and furthermore may have a deleterious effect on the final use of the Plutonium, it cannot be allowed to contaminate the recovered and purified Plutonium. No practical process for separating Neptunium from Plutonium has been developed. Therefore, two months storage between the pile and recovery operations must be provided to allow the Neptunium content of the pile product to be transformed almost completely into Plutonium, as well as to allow the radioactivity of the pile product to be reduced by decay to a level reasonably safe for recovery operations. At the high intensity of large-scale pile operation, various isotopic modifications of Plutonium may be formed of which little is known. These, unlike Neptunium, may persist in the treated uranium after storage and interfere with the Plutonium recovery and purification processes or too greatly increase the radioactivity of the purified Plutonium.

There may be as great difficulty in modifying or repairing recovery units in which operation has been attempted, as in modifying or repairing piles; on account of the absorption of radioactive materials by the recovery equipment and the difficulty, if not impossibility, of washing these absorbed radioactive materials out of the recovery equipment so that it can be approached and handled safely. However, individual recovery units can be small and can be made of less critical materials than pure graphite and uranium. Therefore, individual recovery units can be provided in sufficient number so that forced abandonment of a recovery unit is not so serious a matter as abandonment of a pile.

All waste solutions resulting from dissolving the treated uranium and from the series of the precipitations and re-solutions employed in the recovery and purification of the Plutonium, will contain uranium or radioactive by-products or both. These wastes will be corrosive, will evolve heat spontaneously for long periods, and because of their radioactivity may not be discharged either into the river or into the ground and so must be stored indefinitely. Accordingly, facilities must be provided for isolated, cooled and shielded waste storage in the amount of 25,000,000 gallons for each year’s operation of the Plant at full capacity.

The value of the uranium contained in these waste solutions will be very great, and under normal conditions attempts would be made to reclaim this uranium. However, no process has been developed for reclamation nor could such a process be developed in sufficient time to be of use in the present undertaking without seriously affecting the effort available to more nearly assure the production and recovery of Plutonium. Accordingly, no provision looking to reclamation will be made beyond safe and permanent storage. The radioactive by-products in the waste solutions may be of value for various scientific purposes or for military use; but for the same reasons as apply to uranium reclamation, the salvage of radioactive by-products is not a part of the work contemplated under the Contract.

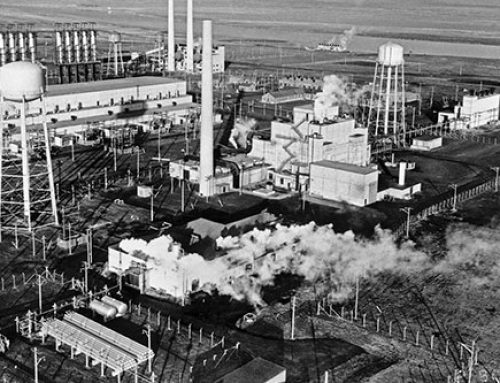

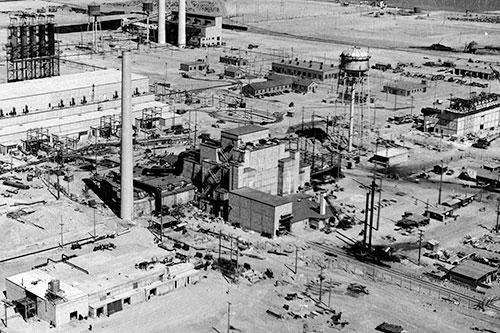

The site of the Plant, to be called the Hanford Engineer Works, has been designated by the Government as a tract of land in Benton, Grant and Franklin Counties, in the State of Washington, where about 195 square miles are being purchased by the Government for use as an operating area, and about 400 square miles surrounding the operating area are being leased by the Government to prevent occupancy except under Government control, and about 25 square miles at a distance of about 15 miles from the nearest edge of the operating area are being purchased by the Government for construction of shops, laboratories and test units, an administration area, and a village to house Plant personnel. The operating area is bounded by the Columbia River, by protecting ranges of hills and by the controlled area extending to the village location. The Columbia River will furnish the needed large pure and cold water supply for the plant. Power in the required considerable amounts will be secured from the Bonneville-Grand Coulee installations. Three railroads pass near the site and a branch line of one of them enters it. Meteorological conditions affecting the air transport of radioactive gases and radioactive dusts and smoke to areas in the neighborhood of the site, were investigated in the course of selecting the site.

The site was chosen with the specifications that no main railroad line or main public highway should be within ten miles of any pile or recovery unit in the operating area, and that no town of population greater than 1,000 should be within twenty miles of the operating area. The nearest large cities, Spokane and Seattle-Tacoma and Portland, are about 125 and 135 and 150 miles away, respectively. The nearest communities of appreciable size, Yakima and Pasco, are about 36 and 33 miles from the nearest pile, respectively. The Plant village will be about 26 miles from the nearest pile and 22 miles from the nearest recovery unit. On the site, the three piles and two recovery areas are being laid out so that the distance between piles will be 6 to 7 miles, the distance between recovery areas will be about 4 miles, and the shortest distance between any pile and a recovery area will be over 3 miles. The site layout provides for five more piles and one more recovery area and expansion of each of the first two recovery areas, should such additions prove to be desirable.

In selecting and laying out the site, and in designing and constructing the Plant, it has been necessary to take into account the possibility of sabotage and other enemy action. Stringent security measures have governed and will govern all research, design, procurement, construction and operation procedure, in order that the utmost secrecy may be maintained. Relatively few individuals engaged in the work have full knowledge regarding it. Other personnel is divided into groups each possessing only such information as is necessary for its own use in connection with its own part of the work. Engineers and supervisors are told what must be done but not why. Draftsmen and construction workers have, and operators will have, no information regarding the purpose of their work, much less its urgent importance. Extreme secrecy has adversely affected speed, quality and assurance of performance, and will continue to do so.

The conduct and control of the transmutation and recovery processes, and the determination of radiation levels in and around all operating equipment and throughout the Plant site and adjoining areas for protection of operating personnel and inhabitants of the neighborhood of the Plant, demand large numbers of electronic and other instruments of diverse types and sensitivities. Many of these instruments have had to be developed in the course of the research leading to the present state of the transmutation and recovery processes. Development has not been carried to the point of readiness for commercial production in several critical areas. The procurement of the necessary instruments, the training of personnel in their use, and their maintenance in use, may delay and hamper completion and operation of the Plant. On account of the serious instrument problem which is faced in design, construction and operation of the Plant, the Plant will include rather large instrument shops and laboratories.

Numerous changes have been made in the proposed scope of the work, both in the type and size of units and apparatus and in the number of units which will be constructed. Other changes will be made as additional information is obtained and design and construction proceed. Initially, piles operating at high temperature and cooled by helium gas under pressure instead of water, were considered. Serious difficulties encountered in design, and foreseeable grave problems of procurement, construction and operation, combined to indicate that the helium-cooled pile is undesirable and relatively inoperative as compared with the water-cooled pile. Accordingly, it is planned to construct water-cooled piles.

So-called “heavy water” (pure deuterium oxide) might be employed instead of pure graphite for slowing the neutrons in the piles. On the basis of present very incomplete information “heavy water” appears to have physics advantages over graphite and may have engineering advantages. However, “heavy water” is not available in more than small quantities, and will become available only slowly and in amounts too small to serve for the earliest production of the desired quantities of Plutonium. Moreover, as beforesaid, information necessary for successful use of “heavy water” is very incomplete. Therefore, inasmuch as time and military considerations must govern, it has been agreed that graphite should be used in the Plant.

The estimated cost of the work under the Contract has been calculated by the Contractor before completing designs or even concluding its study of the processes to be used in the Plant. Therefore, the Contractor offers the cost figures in the Contract as rough estimates only; intended to be, but not sure to have been, conservatively calculated. It is the Contractor’s understanding that speed and assurance of production coupled with safety in operation, are the paramount objectives in the work; and that cost is secondary, though never to be left out of consideration.

It is not possible to estimate the capacity of the Plant except with accuracy so small that estimates based upon it are altogether tentative. The ability to remove heat and at the same time maintain the temperature below the range where excessive corrosion may occur, is the limiting known consideration in the capacity of a pile. The amount of heat evolved per unit of Plutonium formed, estimated to be 1000 kilowatt-days per gram, is known only with an estimated accuracy of plus or minus 20%. Ability to remove heat as planned can be proved only by actual operation of a pile. Similarly, the time required for charging and discharging the piles, and the speed and efficiency of the recovery process, can be determined only by experience. The construction of four 250,000-kilowatt piles was planned initially, together with recovery equipment to handle the output of four such piles. The roughly estimated capacity of the Plant was then 600 grams (1.3 pounds) of Plutonium per day on the basis of 75% efficiency in pile operation and 80% recovery yield. However, the contemplated military use is stated by the Government to require increments of about fifteen to eighteen kilograms (33-40 pounds) of Plutonium, and the rate of accumulation of these increments is the controlling factor in required capacity. Accordingly, a very tentative forecast production schedule has been prepared by the Contractor, comparing the dates on which various numbers of such increments could be produced by the use of one, two, three or four piles. On the basis of this schedule the Contracting Officer has directed the construction of three piles, together with recovery equipment of corresponding capacity. It would be necessary to operate three 250,000-kilowatt piles at say 90% efficiency and to secure say 90% yield in the recovery equipment now to be provided, in order to produce 600 grams of Plutonium per day. Attainment of such efficiency and yield is improbable short of years of operating experience. At 75% efficiency in pile operation and 80% recovery yield, the estimated capacity of the Plant is now 450 grams of Plutonium per day. However, as beforesaid and for the reasons stated, no estimate of the capacity of the Plant can be other than tentative. The Plant to be constructed under the Contract is therefore to be considered to be a three-250,000-kilowatt-graphite-pile Plant, and not a Plant whose size and specifications are determined by its estimated output.

The Contractor has made plain to the Government its inexperience in radioactivity and in physics as compared with chemistry; particularly its inexperience in nuclear physics, with which no industrial organization in the United States has worked, so far as the Government and the Contractor are aware. The Contractor has stated to the Government its extreme reluctance, because of this inexperience, to undertake the work under the Contract. Nevertheless, the Government has insistently requested the Contractor to undertake the work. The Government has emphasized to the Contractor the extreme importance and urgency of the work, stating that in the opinion of the highest Government authorities the military advantage to the nation possessing a supply of Plutonium is so great that it should be possible to force a victorious end to hostilities merely by military use of a sufficient amount of Plutonium; that available evidence very strongly suggests that the enemies of the United States in the present war are working to produce a quantity of Plutonium or its equivalent; and that there is no defense against military use of Plutonium or its equivalent by these enemies except counteruse. In consequence, the Contractor has agreed to undertake the work, with the distinct understanding that there is no assurance that the Contractor will be able successfully to design, construct and operate the Plant to be provided under the Contract, particularly within the time period covered in the Contract. The necessity and justification for such understanding are evident from the statements of fact and circumstance in this Memorandum.

It is obvious that the construction and operation of the Plant to be provided under the Contract will involve extraordinary hazards to life and property. Some of these hazards are unmeasurable, by virtue of the newness of the technical field and the incompleteness of the information available. Hazards not now foreseen at all, may be met. Under these circumstances, the resources of the Contractor, when undertaking the work for national war effort reasons only, cannot justly be placed in jeopardy. The Contractor will conduct the work as safely as its judgement based on experience and on advice given it at the instance of the Government, will permit; but the Contractor cannot and does not accept responsibility for the results of its exercise of judgment, or for the acts or omissions of its employees directly involved in the work, as they may affect the outcome of the work or the lives and property of its employees or others. Pursuant to the terms of the Contract, the Government has accepted this responsibility and will hold the Contractor harmless accordingly.

The Contractor has no knowledge and expresses no opinion regarding the ability of Plutonium to perform the military functions which it is calculated to have; and regarding the practicability of handling quantities of Plutonium with safety; and regarding the composition and form into which Plutonium must be put to perform its military functions; and regarding the individual and total amounts of Plutonium required to perform these functions. The work to be done by the Contractor under the Contract will include only the delivery to the Government, on the Plant site, of such quantities of Plutonium as may be produced during the period of the Contract, in such composition and form as are required by the specifications subsequently agreed to. The Government assumes full responsibility for the Plutonium when so delivered.

The Contractor has had no part in the research which has resulted in the discovery and development to their present state of the transmutation process for production of Plutonium and the chemical process for recovery of Plutonium from the crude product of the transmutation process. The research has been conducted by the University of Chicago and others, largely under the auspices of the Government. Continued research, including the operation of the semi-works plant and studies of the health hazards involved in the transmutation and recovery processes, which will be conducted during the period of design, construction and operation of the Plant to be provided under the Contract, will be done by the University of Chicago and others under Government sponsorship. The results of the research to date, and of the continuing research carried out by the University, are being supplied to the Contractor at the instance of the Government. From time to time, the Contractor will request additional information from the University. At the instance of the Government, the University will attempt to develop this information by studies and experiments. The Contractor will confine its efforts to the interpretation and application of the research results, except as developmental and other technical work may be required at the Plant in an attempt to overcome difficulties which may arise in the course of operation. The University has concurred in all major technical decisions made and acted upon by the Contractor prior to or coincident with approval by the Government; and the University, at the instance of the Government, will review all such technical decisions yet to be made as well as the essential technical details of planned operation procedures, and concur before the Contractor acts upon the decisions or begins use of the procedures.

The research performed by the University includes development of the transmutation process and chemical recovery procedures, and investigation of the nature of the health hazards involved. No obstacle has as yet appeared in those investigations that proves the impracticability of carrying through the production of Plutonium successfully and safely. The large-scale Plant is, however, expected to produce Plutonium a hundred thousand times faster than is being done in the laboratory. Considering the many new problems that may arise from this and other sources, the University can in no way guarantee to the Government or the Contractor the success of the process under Plant conditions of operation, or the absence of damage to personnel and property.

Although the Contractor is experienced only in industrial operations based on chemistry, and has never dealt with industrial operations based on nuclear physics, or with any process involving radioactivity in any degree or form it is the Contractor’s judgment, limited by its inexperience in the fields involved, that the transmutation process for production of Plutonium and the chemical process for recovery of Plutonium ultimately can be put into successful operation. The discovery of these processes and their development to their present state in so short a time and in the face of many handicaps, are extraordinary accomplishments. From its experience with the development of chemical processes from the laboratory scale to the commercial plant, the Contractor would expect that successful large-scale operation of the transmutation and recovery processes would require approach by way of more and longer-continued successive steps on the laboratory, the semi-works, the pilot-plant, and the initial-unit scales, than are included in the present enterprise as now planned. However, as stated, in the opinion of the highest Government authorities the critical importance of time in obtaining quantities of Plutonium justifies the present program; and the Contractor believes that barring factors now unforeseen or the too-adverse effect of factors mentioned in this Memorandum, it will be able to produce Plutonium with the cooperation of the University of Chicago and the Corps of Engineers.

Approved and Agreed to

UNITED STATES OF AMERICA

by_________________________

Witness

___________________________

UNIVERSITY OF CHICAGO

by ________________________

Witness

___________________________

E. I. DU PONT DE NEMOURS & CO.

by ________________________

Witness

___________________________